Maintenance of Solar Power Plant with Thermal Drone is very important. Field work, which would normally take weeks, can be done in 1-2 days, and errors that are normally very difficult to detect can be easily detected. Therefore, if you have a solar power plant (land or roof), you should have it checked with a thermal drone at least twice a year.

Solar energy investments are increasing every year and the amount of electricity produced by solar energy is gradually increasing. In our previous article, we shared our information about solar panel efficiency. (See Solar Panel Efficency )

Maintaining Solar Power Plant With Thermal Drone

The continuous increase in solar energy investments has caused solar farms to reach large sizes. In 2019 the solar farm market alone was valued at 261.0 billion.

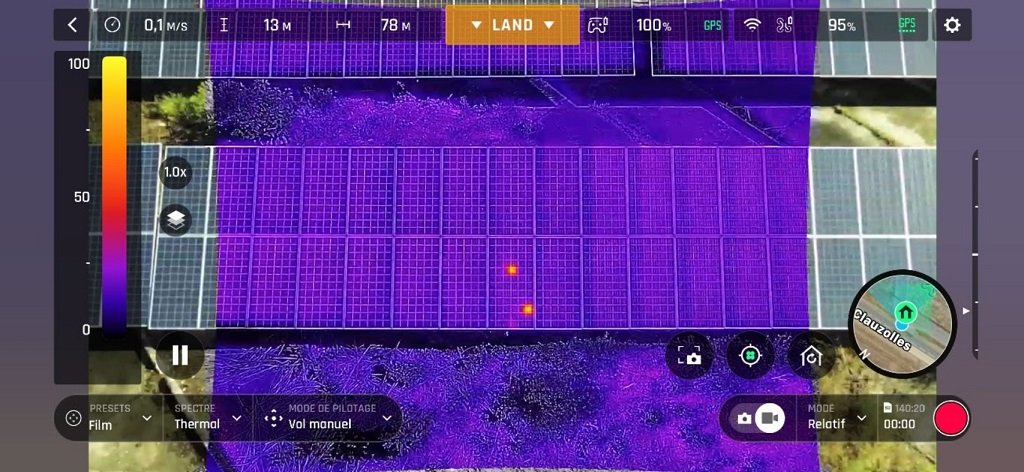

Thermal cameras create an image by detecting the infrared radiation that all objects emit at different levels. This radiation cannot be seen with the naked eye because Infrared light has less energy than the colors we see in the visible spectrum. However, it can be detected with special tools such as thermal cameras.

Sensors in thermal cameras detect unique heat signatures (radiation), which are very subtle differences in temperature, and can therefore detect a wide range of potential anomalies with solar panels.

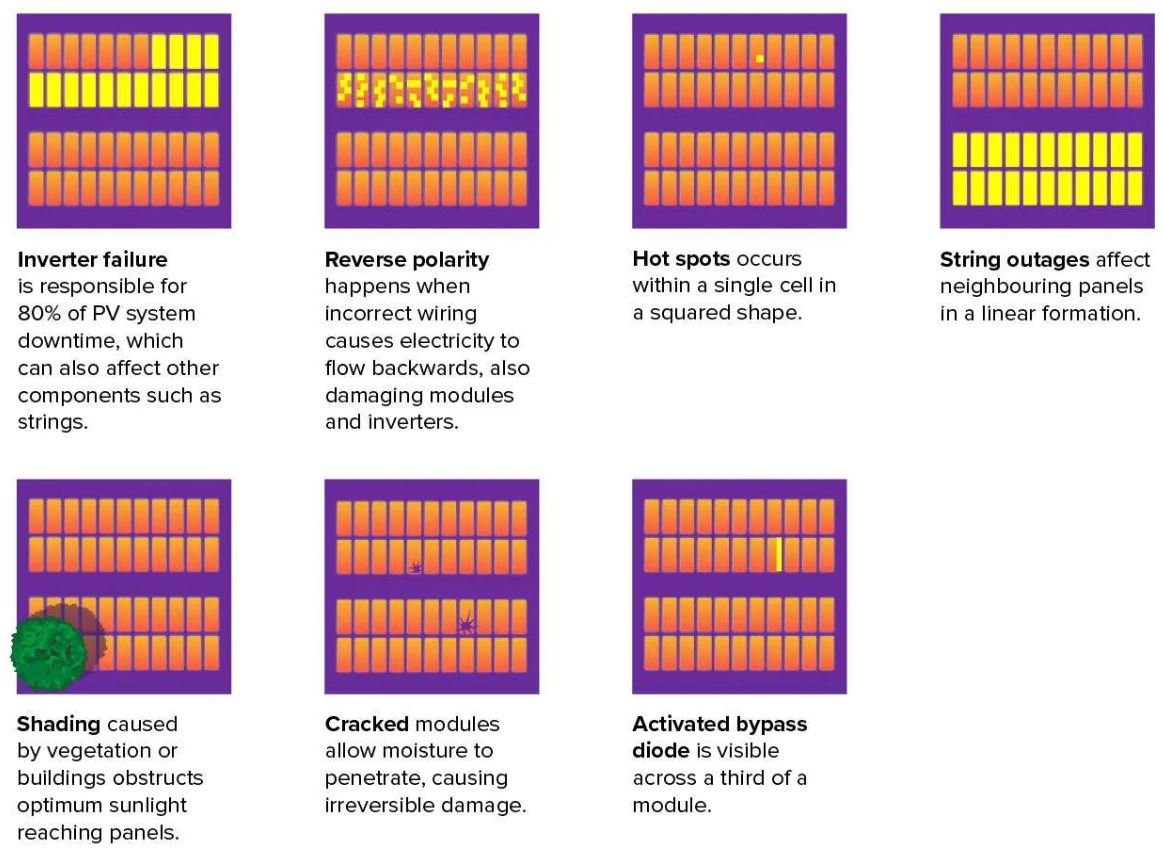

It is possible to detect the following errors in a very short time with the thermal drone.

- Cell Hot Spots

- Module Cracking

- Module Soiling

- Module Delamination

- Activated Bypass Diodes

- String Outages

- Vegetation Encroachment

- Reverse Polarity

- Tracker Faults

Some problems are detected as a result of imaging performed with a thermal drone. You can examine the most common problems and their explanations in the picture above.

Each detected error reduces the efficiency of your panel and causes your power plant to produce less electricity. This reduces your earnings.

Thermal Drone Features

Thermal Drones come in many different qualities depending on demand. A drone with a thermal camera should be purchased according to your needs and your solar power plant should be examined in detail.

The following features should be taken into account for the thermal drone.

Resolution

The resolution in thermal cameras is quite different from other cameras. The resolution of a thermal camera is measured in pixel count. More pixels means the camera can resolve finer details. Solar panel inspections typically require a resolution of at least 640×512 to distinguish finite defects such as cracks and hot spots.

Radiometric

Radiometric thermal cameras can measure the absolute temperature of an object, rather than just its relative temperature. This is important for solar inspections as it allows for more accurate identification of anomaly severity.

Thermal Sensitivity

The thermal camera must be sensitive enough to detect small temperature differences, different sensors are capable of different sensitivity levels.

Field of View

The thermal camera should have a wide field of view to cover a large portion of the installation or array at the intended altitude for the flight.

Lens

The lens affects the focus (sharpness) of the image. A good quality lens will produce a clear image with minimal distortion or refraction.

Frame Rates

The frame rate of a thermal camera is the number of images that the camera can take per second. A higher frame rate means that the camera can capture more detail. For solar inspections, a frame rate of at least 30 FPS is typically required.

Integration with RGB Cameras

Many solar inspection drones are equipped with both thermal and RGB cameras. The thermal camera is used to identify potential defects, while the RGB camera is used for verification of false positives. It is important that

the thermal and RGB cameras are correctly calibrated so that the images from both cameras can be accurately aligned.