Robotics engineering is rapidly evolving, transforming industries, and redefining the future of technology. From manufacturing to healthcare, robotics is revolutionizing how tasks are performed, improving efficiency, and expanding the capabilities of humans. The advancements in artificial intelligence (AI), machine learning, and robotics have opened up new possibilities for automation, precision, and innovation. This article explores the role of robotics engineering in shaping the future, the technologies driving this revolution, and the challenges and opportunities that lie ahead.

What is Robotics Engineering?

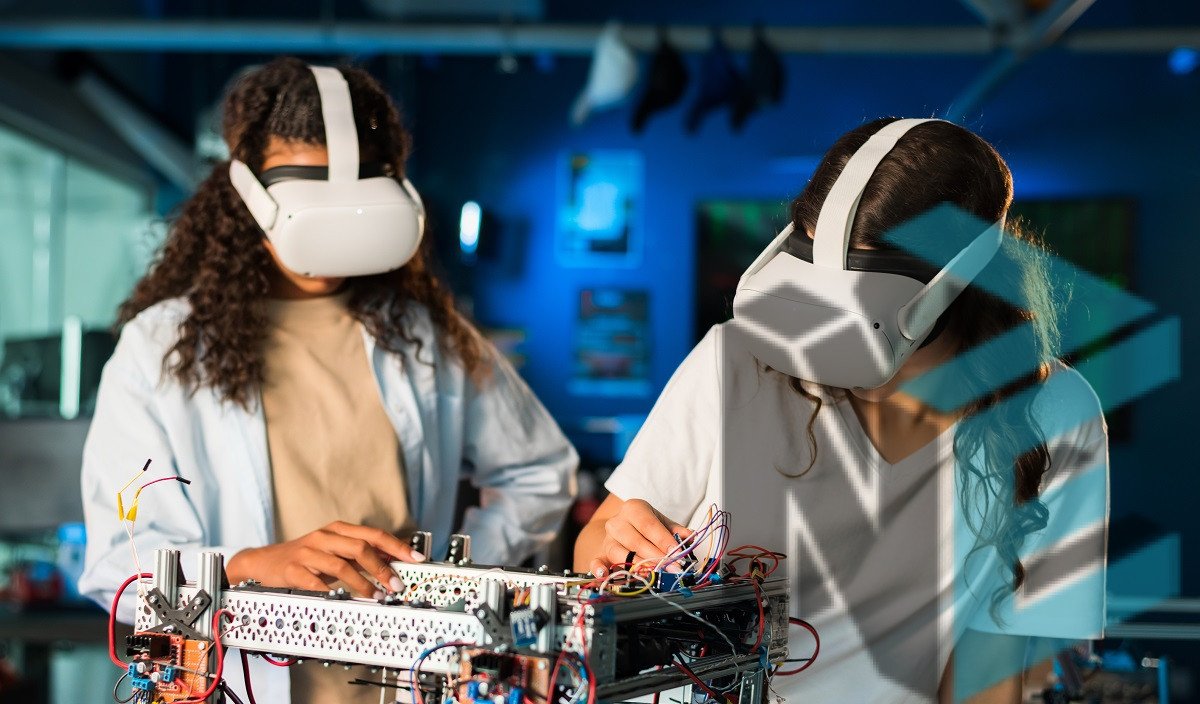

Robotics engineering involves the design, construction, operation, and application of robots in various fields. These machines are often programmed to perform tasks that are too complex, dangerous, or repetitive for humans. Robotics engineers work to improve the functionality of robots, enabling them to operate autonomously, interact with their environment, and perform tasks more efficiently.

The field of robotics is multidisciplinary, combining aspects of mechanical engineering, electrical engineering, computer science, and artificial intelligence. Robotics engineers design both the hardware (mechanical parts) and the software (control algorithms) that allow robots to function.

Key Technologies in Robotics Engineering:

- Artificial Intelligence and Machine Learning: AI and machine learning are critical in enabling robots to learn, adapt, and make decisions based on their environment. These technologies allow robots to perform complex tasks without human intervention. From self-driving cars to robotic assistants in hospitals, AI-powered robots are making their mark across industries.

- Sensors and Perception Systems: Sensors are vital for robots to understand their environment. Vision systems, proximity sensors, and tactile sensors help robots navigate and interact with the physical world. These sensors enable robots to detect obstacles, recognize objects, and respond to changes in their surroundings, making them more autonomous and efficient.

- Actuators and Control Systems: Actuators are the components responsible for moving the robot’s joints and limbs. Robotics engineers use advanced control systems to ensure that the robot’s movements are precise, smooth, and efficient. Innovations in robotics hardware have improved the dexterity, speed, and accuracy of modern robots.

- Collaborative Robots (Cobots): Cobots are designed to work alongside humans in various industries, enhancing productivity and safety. Unlike traditional industrial robots, which operate in isolation, cobots are equipped with advanced sensors and AI systems that allow them to collaborate with human workers, perform delicate tasks, and ensure workplace safety.

- Humanoid Robots: Humanoid robots, designed to mimic human movements and functions, represent the cutting edge of robotics engineering. These robots are used in research, entertainment, healthcare, and even personal assistance. Advances in AI and robotics have made humanoid robots more lifelike and capable of performing tasks that were once reserved for humans.

Applications of Robotics Engineering:

- Manufacturing and Industry: Robotics engineering has transformed the manufacturing sector through automation. Industrial robots perform tasks like assembly, welding, and painting with speed and precision, reducing the need for manual labor and increasing production efficiency. The integration of AI and machine learning has also made industrial robots more adaptive to complex production lines.

- Healthcare: In healthcare, robotics engineering has led to the development of surgical robots, robotic prosthetics, and rehabilitation devices. Robots like the Da Vinci surgical system assist surgeons in performing minimally invasive procedures with greater precision, reducing recovery times for patients. Robotics is also being used to improve patient care, assist in rehabilitation, and provide emotional support through robotic companions.

- Logistics and Supply Chain: In warehouses and distribution centers, robots are revolutionizing the logistics industry by automating tasks such as sorting, packing, and inventory management. Companies like Amazon and Alibaba use robotic systems to streamline operations and reduce human error in their supply chains. Autonomous vehicles and drones are also being developed to handle last-mile delivery, making logistics more efficient and cost-effective.

- Exploration and Space: Robotics engineering plays a crucial role in space exploration. Robotic rovers, like NASA’s Perseverance, are used to explore distant planets, gather data, and perform experiments in environments that are too harsh for humans. In the future, robots are expected to assist in building structures on the Moon and Mars, paving the way for human settlement.

- Service Robots: Service robots are designed to perform tasks in everyday environments, such as cleaning, customer service, and food delivery. Robotic vacuum cleaners, autonomous delivery robots, and robotic waiters are becoming increasingly common in homes, restaurants, and public spaces. These robots improve convenience and free up time for humans to focus on more complex tasks.

Challenges and Opportunities in Robotics Engineering:

- Ethical and Safety Concerns: As robots become more integrated into society, ethical concerns arise about job displacement, privacy, and the potential misuse of AI. Engineers must ensure that robots are designed with safety protocols, transparency, and accountability in mind. The development of ethical frameworks for AI and robotics will be crucial as the technology advances.

- Energy Efficiency: Robotics systems require a significant amount of energy to operate, particularly in applications involving heavy machinery or autonomous vehicles. Engineers are exploring ways to improve energy efficiency by developing lightweight materials, optimizing control algorithms, and integrating renewable energy sources into robotic systems.

- Human-Robot Interaction: As robots increasingly interact with humans, improving human-robot communication and collaboration is essential. Engineers are working to make robots more intuitive, user-friendly, and able to understand human emotions and intentions. This will be especially important in fields like healthcare, where robots work closely with vulnerable populations.

- Cost and Accessibility: While robotics technology is advancing rapidly, high costs remain a barrier to widespread adoption, particularly for small and medium-sized enterprises (SMEs). Reducing the cost of robotic components and improving scalability will be key to making robotics more accessible to a broader range of industries.

The Future of Robotics Engineering:

The future of robotics engineering promises even greater innovation. Advancements in AI, sensor technology, and robotics hardware will lead to the creation of robots that are more autonomous, intelligent, and capable. In industries like healthcare, logistics, and space exploration, robotics will continue to break boundaries and solve complex problems.

In the long term, robotics engineering may play a crucial role in addressing global challenges such as aging populations, labor shortages, and environmental sustainability. Robots will become more embedded in daily life, offering new solutions to pressing issues and enhancing human capabilities.

Robotics engineering is driving a technological revolution that is reshaping industries and society as a whole. From manufacturing to healthcare, robots are expanding the boundaries of what is possible, making tasks more efficient and safe. As technology continues to evolve, robotics will play an ever-increasing role in solving global challenges and shaping the future.